When it comes to temperature-sensitive shipping, maintaining the ideal temperature throughout transit is critical. Whether transporting pharmaceuticals, fresh food, medical samples, or perishable goods, the integrity of the shipment depends on one thing, consistent thermal control. This is where gel ice packs become indispensable. Unlike traditional ice, gel ice packs are scientifically engineered to regulate and maintain stable temperatures over extended periods, ensuring products arrive fresh, potent, and uncompromised.

Understanding the Science Behind Gel Ice Packs

Gel ice packs are composed of a refrigerant gel sealed inside a durable, leak-proof plastic pouch, typically made from HDPE (High-Density Polyethylene). The gel formulation is designed to absorb and release thermal energy gradually, enabling it to maintain a specific temperature range for longer than regular frozen water.

The phase change process is at the core of their performance. When frozen, the gel absorbs heat from the surrounding environment as it transitions from solid to liquid. This slow melting process helps control the internal temperature of the shipping container, keeping contents cool even under fluctuating external temperatures.

Why Gel Ice Packs Are Superior to Regular Ice

While regular ice melts quickly and causes potential water damage to packaging, gel ice packs are clean, reusable, and highly efficient. Here are key advantages that make them the superior choice:

1. Longer Cooling Duration

Gel packs remain frozen up to 30% longer than water-based ice, offering extended temperature control during long-distance or international shipping.

2. Leak-Proof and Hygienic

Since the gel is sealed within a puncture-resistant HDPE film, there’s no risk of water leakage that could damage packaging or contaminate products.

3. Reusability

Unlike traditional ice that disappears after melting, gel ice packs can be refrozen and reused multiple times, making them cost-effective and eco-friendly.

4. Temperature Customization

Manufacturers can engineer gel formulas to maintain specific temperature ranges—such as 0°C, -5°C, or -20°C—depending on the shipping requirement.

How Gel Ice Packs Keep Shipments at the Right Temperature

Maintaining the perfect shipping temperature depends on a combination of thermal mass, insulation, and controlled release of cold energy. Gel ice packs achieve this through precise phase change materials (PCMs) that regulate heat transfer.

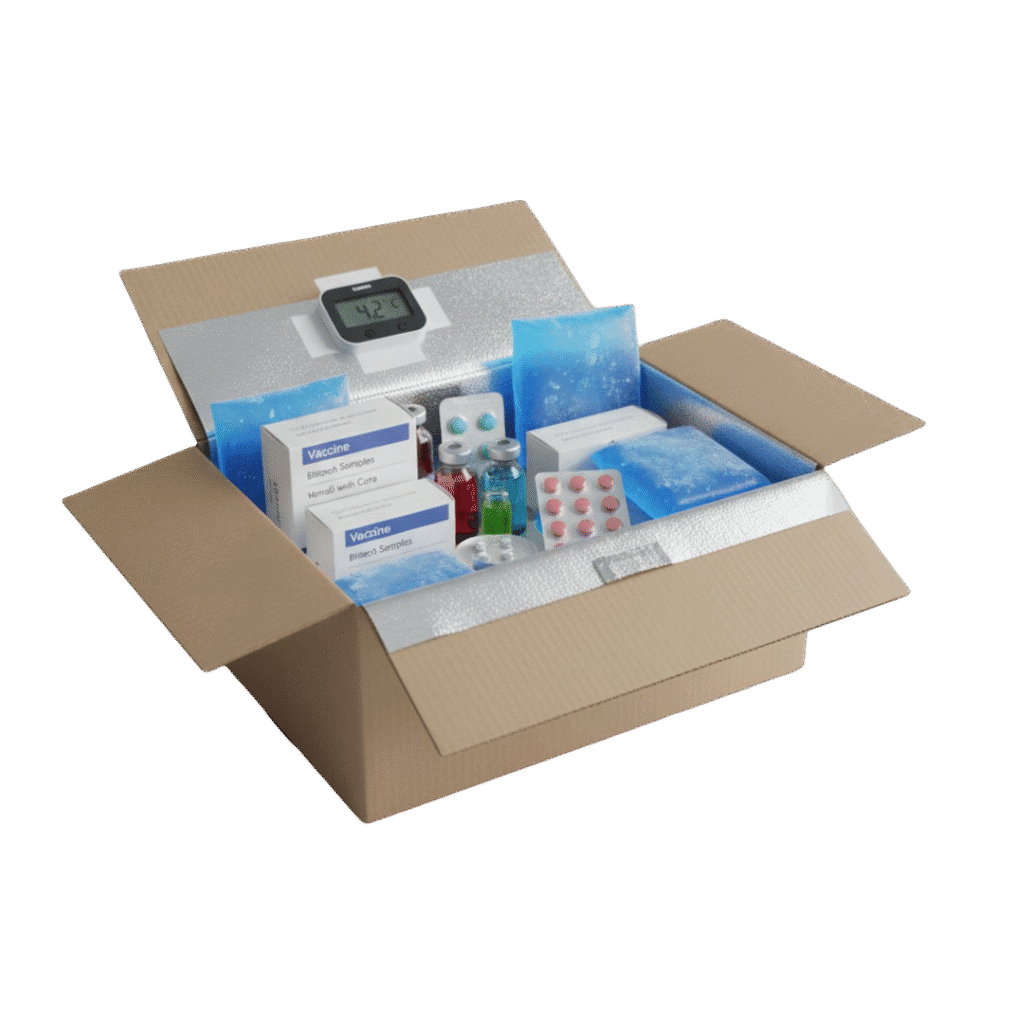

When packed inside an insulated container, gel ice packs act as thermal barriers, absorbing heat that seeps in. This slows down temperature fluctuations and stabilizes the internal environment. For example, food shipments remain below 4°C, and pharmaceuticals stay within their safe storage range between 2°C and 8°C.

The result is consistent cooling performance, even during delays, extreme weather, or last-mile delivery.

Applications of Gel Ice Packs in Temperature-Controlled Logistics

1. Food and Beverage Shipping

Fresh seafood, dairy, meat, fruits, and vegetables rely on gel ice packs to preserve freshness and prevent spoilage. These packs ensure that food products meet stringent cold-chain requirements until they reach their destination.

2. Pharmaceutical and Biotech Shipments

For medical shipments like vaccines, blood samples, and biologics, temperature fluctuations can compromise safety and efficacy. Gel ice packs designed for precise thermal ranges ensure compliance with GMP and GDP regulations.

3. E-commerce and Meal Kit Delivery

The rise of online grocery and meal delivery services has amplified the demand for eco-friendly, reusable cooling solutions. Gel ice packs maintain product quality while being safe for consumer handling.

4. Industrial and Laboratory Applications

In laboratories, gel ice packs are used to transport temperature-sensitive reagents and samples, preventing degradation during transit or fieldwork.

Choosing the Right Type of Gel Ice Pack for Your Needs

Selecting the correct gel ice pack depends on the temperature range, duration, and product sensitivity. Below are common types used in logistics:

- Standard Gel Packs (0°C): Ideal for perishable food shipments.

- Cold Gel Packs (-5°C to -20°C): Suitable for pharmaceuticals and biological samples.

- Phase Change Gel Packs: Designed for highly regulated cold chain environments, providing precise temperature stability.

- Eco-Friendly Gel Packs: Contain biodegradable gels and recyclable HDPE pouches, supporting sustainable shipping practices.

The Role of HDPE Packaging in Performance and Sustainability

The HDPE plastic casing used in gel ice packs is not only durable and puncture-resistant but also recyclable. This material ensures that the pack withstands repeated freezing cycles without losing integrity. Moreover, it prevents leaks, maintains hygiene, and supports eco-conscious business operations by reducing single-use plastic waste.

HDPE gel packs can also be customized in various sizes and shapes, fitting snugly into coolers, cartons, and insulated boxes, enhancing space efficiency and uniform cooling.

Maintaining Temperature Consistency in Global Supply Chains

In global logistics, maintaining temperature consistency can be challenging due to varying climates and long transit times. Gel ice packs, combined with advanced packaging solutions, provide reliable thermal control across air, land, and sea shipments.

They ensure compliance with international cold chain standards such as WHO PQS, IATA, and ISO 9001, making them a trusted choice for exporters of pharmaceuticals and perishable commodities worldwide.