Blow Moulding Machine: Revolutionizing Plastic Manufacturing

The blow moulding machine is the beating heart of the plastic manufacturing industry. It’s the powerhouse that transforms raw materials into a vast array of plastic products, from everyday bottles to complex automotive components. This article delves into the world of blow moulding machines, exploring their inner workings, types, applications, and impact on various industries.

Types of Blow Moulding Machines

Blow moulding machines come in different variations, each tailored to specific production needs. Extrusion blow moulding, the most common type, creates hollow shapes like bottles by extruding melted plastic through a die and then blowing it into a mold. Injection blow moulding, on the other hand, produces smaller, intricate parts such as medical devices. Stretch blow moulding is ideal for producing PET bottles with excellent clarity and strength. Understanding the nuances of each type is vital for selecting the right machine for a given application.

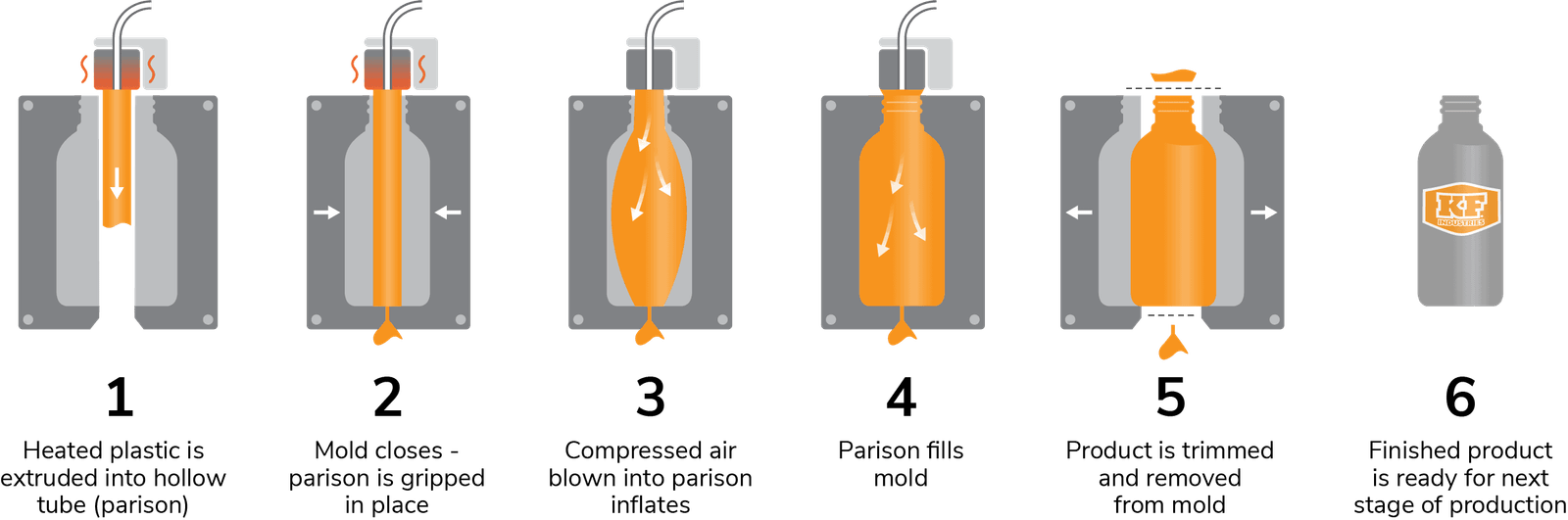

The Blow Moulding Process

At its core, blow moulding is a cyclic process. It begins with the introduction of raw materials, typically high-density polyethylene (HDPE) resin and color masterbatches, into a hopper. The machine’s screw barrel then feeds the resin into a controlled-temperature zone where it melts into a viscous, molten plastic. The magic happens as this molten plastic is extruded, cut into a predetermined parison, and blown into the shape of a mold using compressed air. After the product takes its final form, it’s rapidly cooled to retain its shape.

Applications Across Industries

Blow moulding machines are the workhorses behind the production of countless everyday items. The packaging industry relies heavily on these machines to create plastic bottles, containers, and jars. In the automotive sector, blow moulding produces components like air ducts, fuel tanks, and interior trim. Medical equipment, toys, and even industrial drums owe their existence to this versatile manufacturing process.

Innovation and Sustainability

The blow moulding industry is not stagnant. Continuous innovation has led to advancements such as multi-layer blow moulding, which improves product performance, and the use of recycled materials for a more sustainable future. As the world focuses on environmental responsibility, blow moulding plays a crucial role in recycling plastics and reducing waste.

Conclusion

Blow moulding machines are the unsung heroes of the plastics industry, shaping our modern world one product at a time. Their versatility, efficiency, and capacity for innovation make them indispensable in various sectors. As technology evolves and sustainability takes center stage, the future of blow moulding machines looks promising, offering eco-friendly solutions for a wide range of industries.