Process of Blow Moulding

Mixing HDPE Resin and Color Master Batches

Inception: Combining HDPE Resin and Color Master Batches

To commence the process, we use Blow Moulding and blend HDPE resin and color master batches, setting the foundation for subsequent stages.

Resin Transformation and Plastic Conversion

Metamorphosis: Resin Melting and Plastic Formation

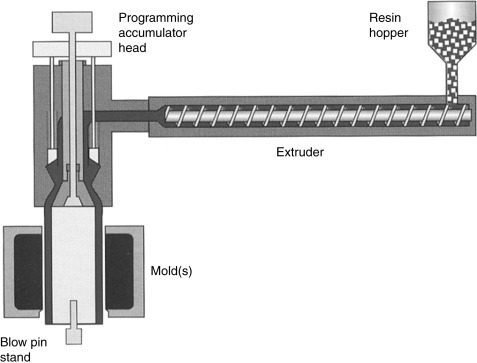

The resin mixture enters the machine’s hopper, where it undergoes a controlled temperature melt, transmuting into molten plastic.

Precise Extrusion and Parison Crafting

Refinement: Controlled Extrusion and Parison Shaping

Meticulous extrusion under the guidance of a controlled-speed screw barrel sculpts the plastic into a parison.

Mold Closure and Excess Elimination

Precision Sculpting: Molding and Excess Material Trimming

The molds encase the parison, and precision prevails as a metal knife expertly trims any superfluous material.

Forming with Dry Air through Blow Moulding

Expansion Artistry: Shaping with Dry Air

Dry air, introduced through a blow pin, expands the plastic, crafting the desired container shape with finesse.

Solidifying for Endurance from Blow Moulding

Endurance Creation: Cooling for Permanence

To cement the container’s shape, it undergoes a meticulous cooling process, resulting in a robust and lasting HDPE plastic container.

Elevate Your Packaging with Plastocraft.pk's Expert Blow Moulding Services

Experience Innovation: Discover how Plastocraft.pk revolutionizes blow moulding to cater to your unique packaging needs.

Plastocraft is a large-scale manufacturer of HDPE plastic bottles and containers having an aggregate production capacity exceeding 50 million bottles and containers every year.

Our extrusion moulding machines manufacture HDPE bottles and containers in a wide variety of shapes, volumes, colours, weight and neck sizes. High capacity and high speed fully automatic production lines ensure a faster time to market. Ready stocks and on time deliveries, we make sure you are never out of stock.

We manufacture HDPE containers for the following industry segments:

- Pharmaceutical

- Agriculture

- medicine bottles

- Jerry Cans

- Milk Jugs for Dairy

- Refreezable Ice Packs

- Motor / Engine Oil

- Plastic Gardening

- Pots

- Healthcare and Cosmetics

- Haircare and Hand Wash

- Hand Sanitizer Bottles