In the fast-paced world of cold chain logistics, maintaining temperature integrity and product safety is critical. At the heart of this innovation lies HDPE sheet packaging — a durable, safe, and eco-friendly solution for gel packs used in food delivery, pharmaceuticals, and medical applications. As sustainability becomes a global priority, HDPE (High-Density Polyethylene) stands out for its strength, recyclability, and versatility, redefining how we preserve perishable goods.

What Is HDPE Sheet Packaging?

HDPE sheet packaging is made from High-Density Polyethylene, a thermoplastic polymer known for its high strength-to-density ratio. It’s widely used in industries that demand robust and leak-proof protection, especially for gel ice packs that must endure freezing, thawing, and transport cycles without compromising integrity.

Unlike low-density plastics, HDPE sheets are resistant to cracking, puncturing, and chemical reactions. This makes them ideal for containing gel substances that need long-term stability during temperature fluctuations..

Why HDPE Sheets Are Ideal for Gel Pack Manufacturing

When it comes to gel pack production, packaging quality determines the performance, longevity, and safety of the product. Here’s why HDPE sheets are the preferred choice among manufacturers:

- Exceptional Durability and Strength

HDPE sheets offer superior tensile strength, allowing gel packs to resist tears and punctures even under heavy compression. They maintain structure even when frozen at sub-zero temperatures, ensuring no leakage or rupture during transport or use.

- Leak-Proof and Moisture Resistant

One of the biggest challenges in gel pack packaging is preventing leaks. HDPE’s non-porous structure makes it completely waterproof, preventing moisture exchange between the pack and external environment. This protects both the gel material and surrounding products.

- Safe and Non-Toxic Material

HDPE is FDA-approved for food and medical contact. It contains no harmful additives, making it safe for direct exposure in food packaging, healthcare, and pharmaceutical industries. The material does not leach chemicals, ensuring that perishables and biological products remain uncontaminated.

- Temperature Resistance

From deep-freeze storage to room temperature handling, HDPE retains its integrity. It can withstand temperatures as low as -50°C and as high as 120°C, making it ideal for reusable gel packs in both cold and hot therapy applications.

- Lightweight and Flexible

Despite its toughness, HDPE is lightweight, reducing overall shipping costs. The material’s flexibility allows manufacturers to customize sizes and thicknesses according to product needs — from small personal gel packs to large industrial cooling sheets.

The Sustainability Edge of HDPE Gel Pack Packaging

With increasing global focus on eco-conscious manufacturing, HDPE stands as a sustainable choice. It’s 100% recyclable, minimizing environmental impact while providing long-lasting usability.

Recyclability and Circular Use

After end-of-life, HDPE sheets can be recycled into new plastic products such as pipes, containers, or secondary packaging. This circular approach helps reduce plastic waste and supports green packaging initiatives.

Low Carbon Footprint

HDPE production requires less energy compared to alternative polymers. Its light weight contributes to lower fuel consumption during transport, thus reducing greenhouse gas emissions.

Reusable Packaging Solutions

Many companies now design HDPE-based gel packs for multiple use cycles. This not only saves cost but also reduces single-use plastic waste, aligning perfectly with sustainability goals.

HDPE vs. Other Materials: Why It Outperforms Competitors

When comparing HDPE sheets with materials like LDPE (Low-Density Polyethylene), PVC, or foil laminates, HDPE consistently leads in terms of strength, recyclability, and food safety.

Property | HDPE Sheet | LDPE Sheet | PVC Film | Foil-Laminated Pack |

Durability | Excellent | Moderate | Weak | Good |

Recyclability | High | Medium | Low | Very Low |

Temperature Resistance | -50°C to 120°C | -30°C to 80°C | -10°C to 60°C | -20°C to 70°C |

Food/Medical Safety | FDA Approved | Moderate | Toxic Additives | Not Food-Safe |

Cost-Effectiveness | High Value | Low Cost | Expensive | High Cost |

Applications of HDPE Gel Pack Packaging

The versatility of HDPE sheet packaging extends across multiple industries that rely on temperature control and product protection.

- Food and Beverage Industry

HDPE gel packs help maintain freshness during food delivery and storage. From seafood to frozen desserts, these packs prevent spoilage by maintaining consistent low temperatures.

- Pharmaceutical and Medical Transport

For vaccines, biological samples, and medicines requiring precise temperature conditions, HDPE-sealed gel packs offer uncompromised containment and sterility during cold-chain logistics.

- E-commerce and Grocery Deliveries

With the rise of online food and grocery delivery, HDPE gel packs ensure safe, chilled transport. Their leak-resistant design guarantees mess-free packaging that customers trust.

- Therapeutic and Healthcare Use

Reusable hot and cold therapy gel packs often rely on HDPE films due to their flexibility, chemical resistance, and skin safety, offering comfort and reliability in both professional and home settings.

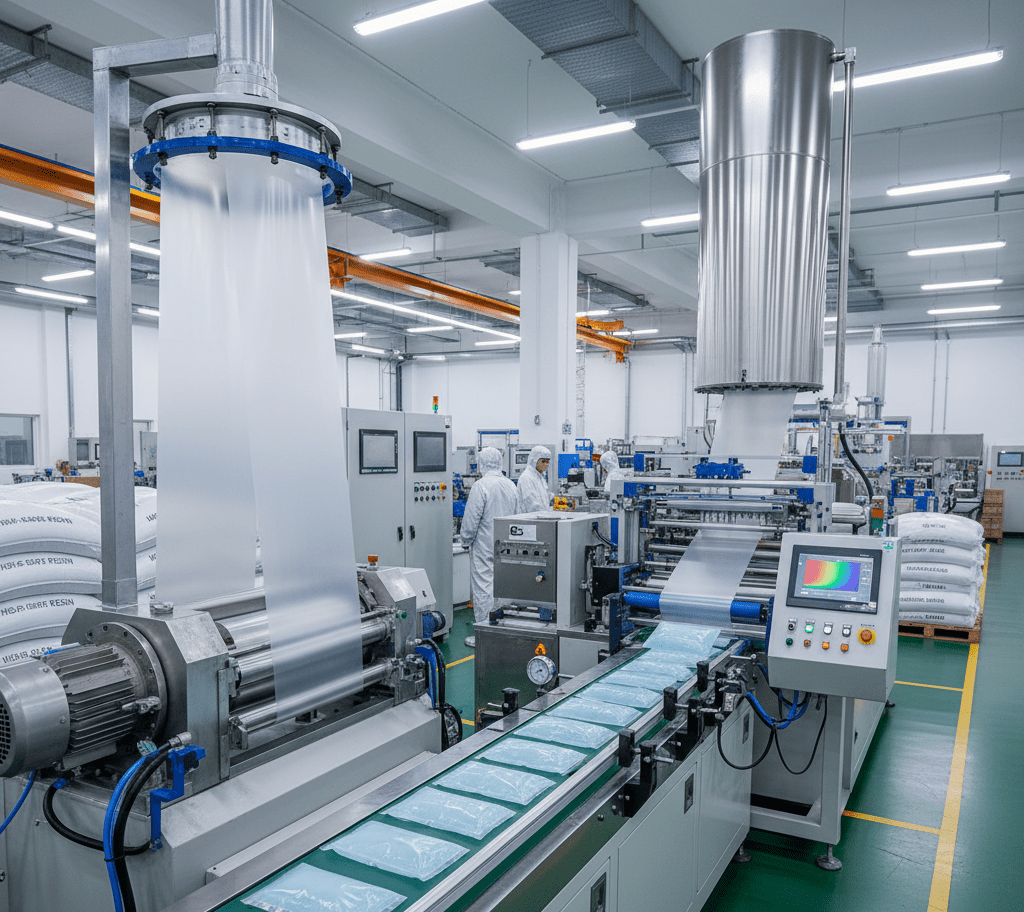

Manufacturing HDPE Gel Pack Sheets

Creating HDPE sheets for gel packs involves extrusion, film blowing, and lamination processes that ensure consistent thickness and sealing strength. Key production steps include:

- Resin Selection: High-grade HDPE resin is chosen for flexibility and clarity.

- Extrusion Process: The resin is melted and extruded into thin sheets or films.

- Cooling and Finishing: Sheets are cooled rapidly to preserve tensile strength.

- Sealing and Filling: The sheets are heat-sealed into desired pack shapes and filled with coolant gel or phase change materials (PCMs).

- Quality Testing: Each pack undergoes rigorous leak, temperature, and durability testing to ensure performance in real-world conditions.

Future Trends: Smart and Biodegradable HDPE Alternatives

The next generation of HDPE sheet packaging is evolving toward smart labeling and biodegradable blends. Researchers are developing bio-HDPE composites that maintain the same durability while enhancing environmental degradability. Meanwhile, smart gel packs embedded with temperature indicators are emerging, allowing real-time monitoring of cold-chain integrity.

These innovations will ensure that HDPE-based packaging remains relevant, sustainable, and efficient for decades to come.